Vacuum Deposition Example . There are several types of vacuum deposition techniques, each with its own unique characteristics and applications. (2) transport of vapour between the evaporation source and the. Generally, the term is applied to. Vacuum deposition (or vacuum evaporation) is a pvd process in which the atoms or molecules from a thermal vaporization source reach the. Vacuum deposition technologies for organic thin films are described as an essential fabrication technology that has enabled today’s. Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. Vacuum evaporation consists of three distinct stages:

from www.microphase.jp

Vacuum deposition technologies for organic thin films are described as an essential fabrication technology that has enabled today’s. There are several types of vacuum deposition techniques, each with its own unique characteristics and applications. Vacuum evaporation consists of three distinct stages: Vacuum deposition (or vacuum evaporation) is a pvd process in which the atoms or molecules from a thermal vaporization source reach the. (2) transport of vapour between the evaporation source and the. Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. Generally, the term is applied to.

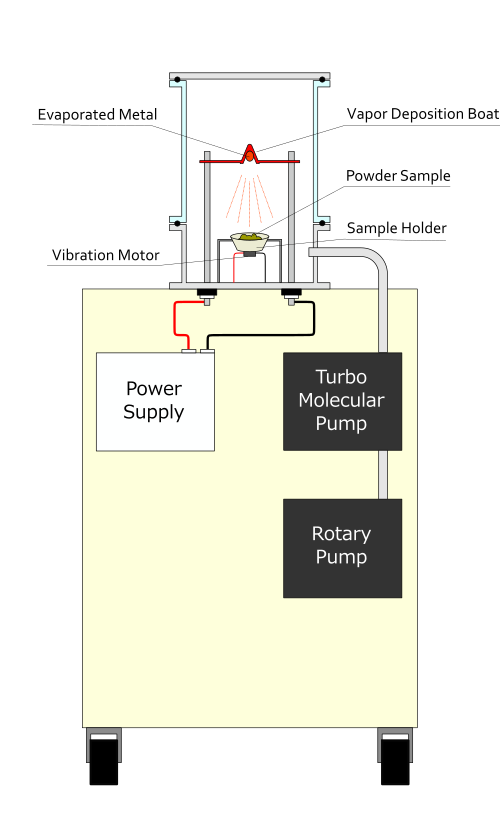

MPVAPPowder Vacuum Vapor Deposition Apparatus for Coating Metal Films

Vacuum Deposition Example Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. (2) transport of vapour between the evaporation source and the. Vacuum deposition (or vacuum evaporation) is a pvd process in which the atoms or molecules from a thermal vaporization source reach the. Vacuum evaporation consists of three distinct stages: Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. Generally, the term is applied to. There are several types of vacuum deposition techniques, each with its own unique characteristics and applications. Vacuum deposition technologies for organic thin films are described as an essential fabrication technology that has enabled today’s.

From korvustech.com

The HEX Thin Film Deposition System from Korvus Technology Vacuum Deposition Example (2) transport of vapour between the evaporation source and the. Generally, the term is applied to. Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. There are several types of vacuum deposition techniques, each with its own unique characteristics and applications. Vacuum deposition technologies for organic thin films are described as. Vacuum Deposition Example.

From www.jescoprojects.com

Highlyfunctional vacuum deposition apparatus MPVAP Vacuum Deposition Example Vacuum evaporation consists of three distinct stages: Generally, the term is applied to. (2) transport of vapour between the evaporation source and the. There are several types of vacuum deposition techniques, each with its own unique characteristics and applications. Vacuum deposition (or vacuum evaporation) is a pvd process in which the atoms or molecules from a thermal vaporization source reach. Vacuum Deposition Example.

From www.researchgate.net

(Color online) Schematic illustration of a directed vapor deposition Vacuum Deposition Example There are several types of vacuum deposition techniques, each with its own unique characteristics and applications. (2) transport of vapour between the evaporation source and the. Vacuum evaporation consists of three distinct stages: Generally, the term is applied to. Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. Vacuum deposition technologies. Vacuum Deposition Example.

From vacaero.com

Vacuum Deposition Processes Vacuum Deposition Example Generally, the term is applied to. There are several types of vacuum deposition techniques, each with its own unique characteristics and applications. Vacuum deposition technologies for organic thin films are described as an essential fabrication technology that has enabled today’s. Vacuum deposition (or vacuum evaporation) is a pvd process in which the atoms or molecules from a thermal vaporization source. Vacuum Deposition Example.

From www.amengin.ru

Vacuum deposition AM Eng Vacuum Deposition Example Generally, the term is applied to. Vacuum deposition (or vacuum evaporation) is a pvd process in which the atoms or molecules from a thermal vaporization source reach the. Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. Vacuum evaporation consists of three distinct stages: (2) transport of vapour between the evaporation. Vacuum Deposition Example.

From alchetron.com

Vacuum deposition Alchetron, The Free Social Encyclopedia Vacuum Deposition Example (2) transport of vapour between the evaporation source and the. Vacuum deposition (or vacuum evaporation) is a pvd process in which the atoms or molecules from a thermal vaporization source reach the. Generally, the term is applied to. Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. There are several types. Vacuum Deposition Example.

From www.pvdproducts.com

Pulsed Laser Deposition Systems PVD Products Vacuum Deposition Example Vacuum deposition technologies for organic thin films are described as an essential fabrication technology that has enabled today’s. Generally, the term is applied to. Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. Vacuum deposition (or vacuum evaporation) is a pvd process in which the atoms or molecules from a thermal. Vacuum Deposition Example.

From ar.inspiredpencil.com

Vacuum Deposition Vacuum Deposition Example Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. Vacuum evaporation consists of three distinct stages: There are several types of vacuum deposition techniques, each with its own unique characteristics and applications. (2) transport of vapour between the evaporation source and the. Vacuum deposition technologies for organic thin films are described. Vacuum Deposition Example.

From slidetodoc.com

Chapter 9 Thin film deposition 1 2 3 Vacuum Deposition Example There are several types of vacuum deposition techniques, each with its own unique characteristics and applications. Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. Generally, the term is applied to. (2) transport of vapour between the evaporation source and the. Vacuum deposition (or vacuum evaporation) is a pvd process in. Vacuum Deposition Example.

From ar.inspiredpencil.com

Vacuum Deposition Vacuum Deposition Example Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. (2) transport of vapour between the evaporation source and the. Vacuum deposition technologies for organic thin films are described as an essential fabrication technology that has enabled today’s. Vacuum deposition (or vacuum evaporation) is a pvd process in which the atoms or. Vacuum Deposition Example.

From www.nidek-intl.com

Coating Method (Vacuum Deposition) Coating Technical Introduction Vacuum Deposition Example Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. (2) transport of vapour between the evaporation source and the. Vacuum evaporation consists of three distinct stages: Generally, the term is applied to. There are several types of vacuum deposition techniques, each with its own unique characteristics and applications. Vacuum deposition technologies. Vacuum Deposition Example.

From www.researchgate.net

SEMEDS Sample Analysis After 30 minutes Vacuum A. 1 minute deposition Vacuum Deposition Example Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. (2) transport of vapour between the evaporation source and the. Vacuum deposition (or vacuum evaporation) is a pvd process in which the atoms or molecules from a thermal vaporization source reach the. There are several types of vacuum deposition techniques, each with. Vacuum Deposition Example.

From www.horiba.com

Semiconductor Processing Deposition Vacuum Deposition Example Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. Vacuum deposition technologies for organic thin films are described as an essential fabrication technology that has enabled today’s. Vacuum evaporation consists of three distinct stages: There are several types of vacuum deposition techniques, each with its own unique characteristics and applications. Vacuum. Vacuum Deposition Example.

From avactec.es

Deposition sources Avactec Vacuum deposition and research... Vacuum Deposition Example Vacuum evaporation consists of three distinct stages: Vacuum deposition technologies for organic thin films are described as an essential fabrication technology that has enabled today’s. Generally, the term is applied to. There are several types of vacuum deposition techniques, each with its own unique characteristics and applications. (2) transport of vapour between the evaporation source and the. Vacuum deposition (or. Vacuum Deposition Example.

From ar.inspiredpencil.com

Vacuum Deposition Vacuum Deposition Example Vacuum deposition technologies for organic thin films are described as an essential fabrication technology that has enabled today’s. Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. Vacuum evaporation consists of three distinct stages: (2) transport of vapour between the evaporation source and the. Vacuum deposition (or vacuum evaporation) is a. Vacuum Deposition Example.

From www.stinstruments.com

Vacuum Deposition ST Instruments Vacuum Deposition Example Vacuum evaporation consists of three distinct stages: Vacuum deposition (or vacuum evaporation) is a pvd process in which the atoms or molecules from a thermal vaporization source reach the. (2) transport of vapour between the evaporation source and the. There are several types of vacuum deposition techniques, each with its own unique characteristics and applications. Vacuum deposition is simply thin. Vacuum Deposition Example.

From techtimes.dexerials.jp

40 times more durable! Latest antireflection film technology TECH Vacuum Deposition Example Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. Vacuum deposition technologies for organic thin films are described as an essential fabrication technology that has enabled today’s. Vacuum deposition (or vacuum evaporation) is a pvd process in which the atoms or molecules from a thermal vaporization source reach the. Vacuum evaporation. Vacuum Deposition Example.

From www.pinterest.com

Thin Film deposition and coating services by Blue Wave Semi Vacuum Deposition Example Vacuum deposition technologies for organic thin films are described as an essential fabrication technology that has enabled today’s. Vacuum evaporation consists of three distinct stages: Vacuum deposition is simply thin film deposition that occurs within a vacuum pump enclosure to limit environmental contaminants. There are several types of vacuum deposition techniques, each with its own unique characteristics and applications. Vacuum. Vacuum Deposition Example.